Aligned Innovations: Polymer Dynamics for Optimized Nanofiber Performance

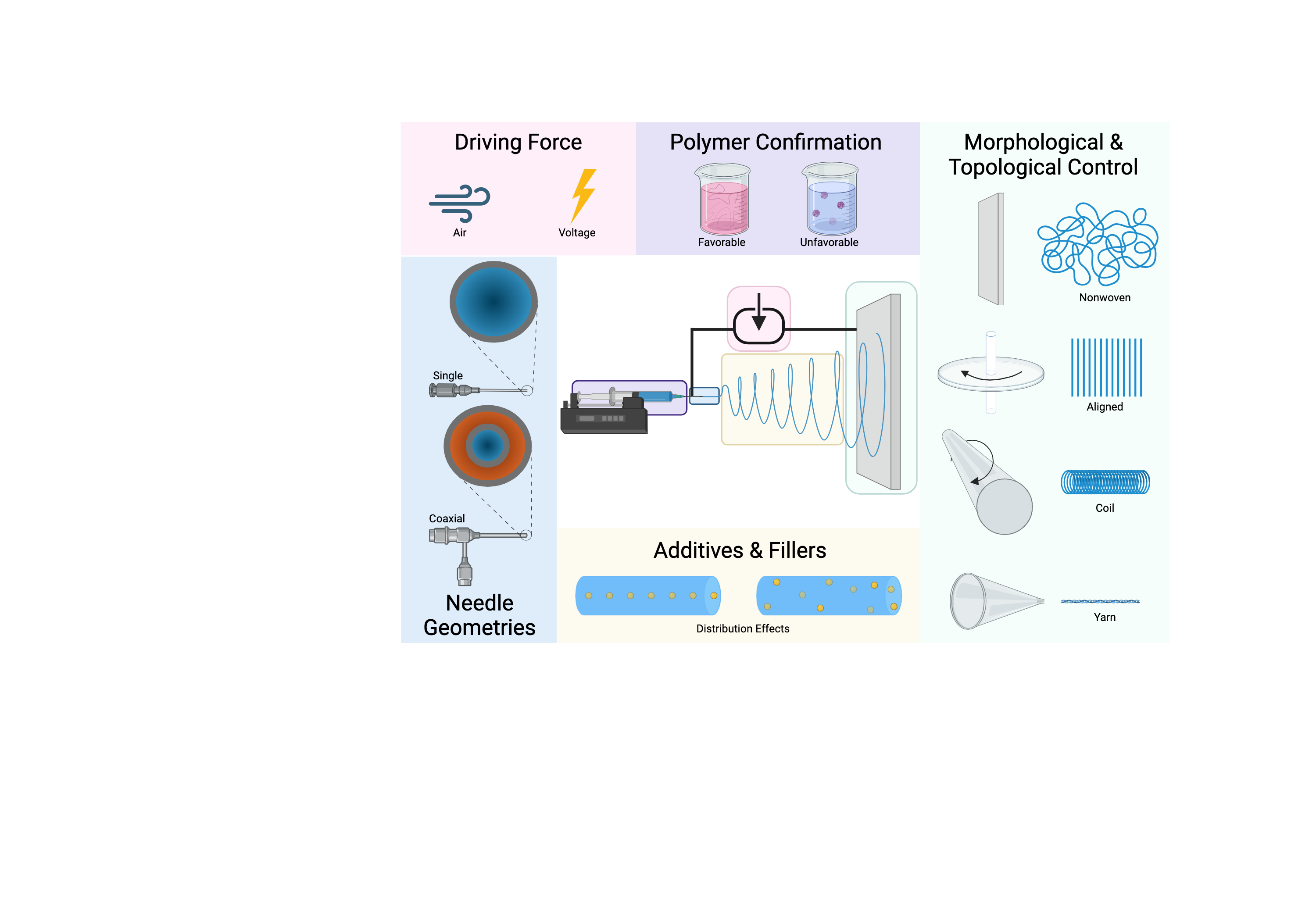

Solution blow spinning (SBS) offers a scalable alternative to electrospinning, using high-velocity gas flow to induce jet elongation without electrical fields. This project establishes quantitative relationships between SBS processing parameters and resulting fiber structure to enable predictive control over nanofiber properties for sensing and energy harvesting applications.

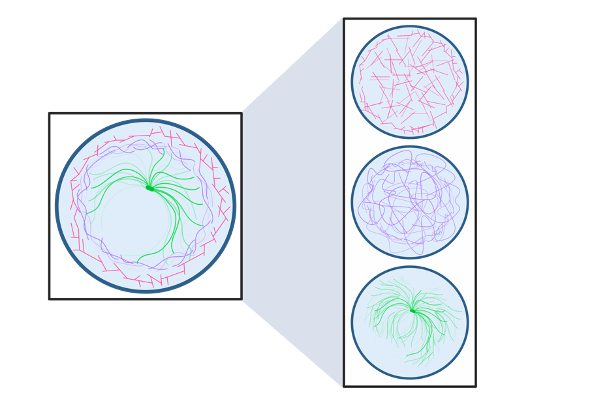

Key objectives: Map the processing window for stable fiber formation, develop methods for controlled aligned nanofiber bundles, and investigate additive incorporation effects on jet stability and final properties.

Target metrics: Piezoelectric response >30 pC/N, strain sensitivity >5 mV/ε, power density >1 μW/cm².